Manufacturing tradition since 1907

Originally the family company of Mr. Lang was engaged in the production of machinery and equipment for the dairy industry. Over time, the company was engaged in the production of machinery and equipment for the food industry, especially slaughtering lines for the poultry industry and operated until 1992 as a mechanization plant of Xaverov Praha, a.s.

Privatisation took place at the turn of 1992 and 1993, when the joint stock company with the present name was established. The production programme at that time included the manufacture, assembly and servicing of machinery, equipment and lines for the slaughter and processing of poultry and rabbits exclusively for domestic customers in the then Czechoslovakia.

Since that year, a gradual restructuring of the production programme has been taking place in response to changes in the surrounding market and the first phase was completed in 1999.

In the following years, the company tried to take advantage of the experience in processing stainless and carbon steels and in 2002 more than 50% of the production was already directed to foreign markets. Traditional equipment for poultry slaughtering and meat processing was still produced, but the production program was expanded to include stainless steel construction elements for food processing plants, various types of conveyors, washers, hoppers, etc. The long experience in stainless steel processing has enabled a gradual growth in the production of machinery and equipment for the metallurgical and food processing industries, from smaller welded and prefabricated structures to parts of larger investment units and lines.

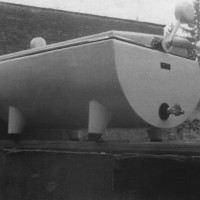

After 2000, the original "clean energy" development programme, which included the production of thermal solar collectors and previously also wind power plants, was extended to include the production of large-scale and facade thermal solar collectors with high efficiency. However, due to variable subsidy conditions, unlike foreign installations of collectors in houses, large solar systems for companies and larger buildings, including apartment buildings, were primarily implemented in the Czech Republic, also under the Green Savings Programmes.

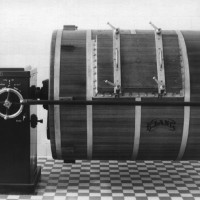

Our own research and development in the energy segment has gradually created the conditions for a targeted focus on high-efficiency technologies in the form of concentrating solar power plants. The economically and technically very demanding research and development of the thermal Stirling engine is one of the key elements enabling the entry into the markets for high-tech equipment producing electricity and heat from the sun. The company is maximizing its efforts and development activities into the CSP Dish Stirling concentrating solar power plant technology. We anticipate that with our proprietary Stirling engine design and concentrating solar power plant technology, we will achieve a very attractive market share in the production and supply of small and medium-sized power plants, decentralized and independent power plants by 2020.

The company also focuses on alternative waste recovery and treatment technologies thanks to its technical and manufacturing skills and capabilities. In addition to composting and fermentation, it is also the energy recovery of waste.